/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/top-Image-min.jpg)

All in One Coding Solution - Contact Us Today!

Printing Solutions for Primary Packaging from KGK JET

India

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/cable_coding22.jpg)

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/High_speed.jpg)

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/High_production.jpg)

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/date.jpg)

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/master.jpg)

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/Protection.jpg)

Primary Packaging Printers

Our Pride - The Wide Range of Industrial Printers for your Precious Products

Continues Inkjet

Printer CCS-R

Print from minimum of 0.8mm to max 10 mm Height

Print minimum 1 line to max 4 lines

Store up-to 512 Characters in the machine

Connect through RS 232 Port

User friendly economic Printer

Value for Money Printer

Inkjet Printer

CCS-3000L

Print with 5.7" colour LCD / touch panel Store up-to a maximum of 4096 Characters

I/O Signal light, RS-232C, LAN, encoder, UPS, USB memory for external connection

Data can be input through Touch panel, RS-232C Communication, Ethernet

Print minimum 1 line to max 4 lines

Inkjet Printer

CCS-3100

IP 65 Rating Dust and Water Proof Printer

Print minimum 1 line to max 6 lines

Print two dimensional QR Code and Data Matrix

Compatible with all types of Dye and Pigment based inks

I/O Signal light, RS-232C, LAN, Encoder, UPS, USB Memory for External Connection

/filters:quality(100)/filters:proportion(1)/ecm.elcom-in.com/customise.jpeg)

Why Wait?

Talk to us now!

Get KGK JET India’s Industrial

Printers.

Boost Your Business, Boost Your

Brand!

The Broad Spectrum of

Industries

that our Industrial Printers Delight!

Crafting Excellence Across Diverse Industries with Our Industrial Printers.

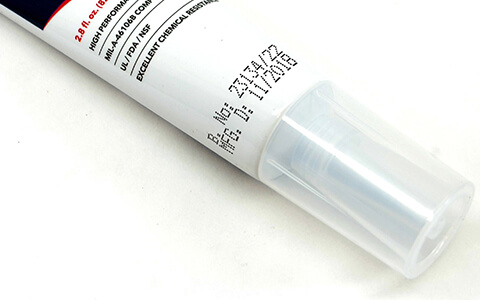

Adhesives

Revolutionize adhesive packaging with our precision printing solutions for enhanced branding and product information.

Agrochemical and Fertilizers

Optimize your agrochemical and fertilizer packaging with our specialized printing, ensuring safety and compliance.

Automotive

Drive brand visibility in the automotive sector with our high-quality packaging printing that reflects the industry's innovation.

Beverages

Quench your brand's thirst for attention with vibrant and captivating packaging printing tailored for the beverage industry.

Building & Construction

Construct a strong brand presence in the building and construction realm through durable and informative packaging printing.

Chemicals

Safeguard your chemical products with packaging printing that communicates essential handling instructions and regulatory details.

Dairy

Enhance the appeal of dairy products with packaging printing that maintains product freshness and communicates nutritional information.

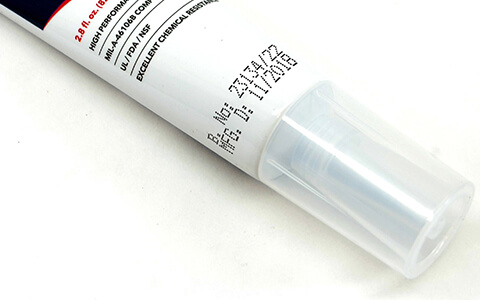

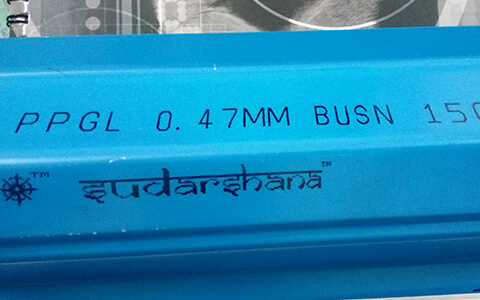

Electricals

Illuminate your electrical product packaging with our printing solutions that highlight technical specifications and safety details.

Extrusion

Shape the future of extrusion packaging with our cutting-edge printing that combines functionality and aesthetics seamlessly.

Packed Foods

Delight consumers with packaging printing that preserves the flavor and integrity of packed food products while conveying appetizing visuals.

Fresh and Frozen Foods

Keep freshness intact with packaging printing designed to withstand extreme temperatures and showcase enticing food visuals.

Personal Care

Elevate personal care product packaging with printing that conveys luxury, efficacy, and necessary usage instructions.

Pharmaceutical

Ensure safety and compliance in pharmaceutical packaging through meticulous printing that includes essential dosage and usage information.

World-Class Technology

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/cable_coding22.jpg)

Stable coding even in humid and dusty environment

New print-head design (P-type) for high-speed & legible coding. Also equipped with Fluorine coated nozzle, which protect print-head from contamination. Positive air pressure inside the print-head, keeps dust and humidity out, resulting in no contamination of head and ink. Operators need not clean print-head before every start & stop.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/Nozze_capping.jpg)

Automatic Nozzle Capping Technology

KGK Jet Patented Nozzle Capping Technology automatically close the nozzle with gutter, if the printer is not in use. This prevents ink getting exposed to external environment and contamination resulting significant savings for customers.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/Uninterrupted-uptime.jpg)

Scheduler: Auto Start & Stop

Designed to start the machine immediately even if machine is not operated for very long time. The customer just needs to keep the power supply ON. As per set schedule time, machine will start automatically and calibrate parameters like fluid viscosity & ink delivery systems. No service engineer visit is required resulting in longer up time for the machine.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/SMS-min.jpg)

Service Management System (SMS)

Service Management System SMS is inbuilt diagnostic tool, a value-added feature of KGK Jet CIJ machine. KGK is committed to the reliability of machine, running cost, timely Preventive Maintenance & uptime of machine in which SMS play an important role. The objective of Service Management System (SMS) is to provide uninterrupted & best quality output.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/Language-min.jpg)

Extended language support & Weighing machine connectivity

Language support for both software & hardware including English, Arabic, Chinese, Korean, Italian, German, Spanish, Iranian & Turkish. Simple & convenient to integrate with on-line or off-line check-weigher machine of any brand through RS-232, TCP/IP(LAN) with the support of weighing machine suppliers.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/Pump.jpg)

Unique diaphragm pump advantage

KGK Jet use diaphragm pump to generate pressure of delivery system. Diaphragm pump is 97% efficient and considered more reliable over geared pump. These pumps generate no heat due to friction and provide stable ink composition for KGK Jet machines, also minimal evaporation of ink & solvent results in more savings.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/DOD_1.jpg)

Print directly on the boxes

KGK Jet DOD technology lets you print directly on box saves on huge inventory on boxes, stickers & manual labour reducing the operational complexity of coding and maximizing space, resulting in significant cost savings. High resolution DOD inkjet printers are the most flexible and effective choice for production lines.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/DOD_3.jpg)

Solution as per print height

KGK's drop on demand printer (DOD printer) can print character height ranging from 1 mm to 130 mm using a single head and a height of 520 mm with 4 heads stitched together. Commonly called a carton box printer, corrugated box printer or large character inkjet printer. Various options to select from desirable print height & resolution.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/DOD_5.jpg)

High Resolution Print

As per customer requirements KGK Jet DOD printer can deliver various print resolution from 50 DPI to 600 DPI (Drop per square inch). The complete customized window based multi head control system can control various print heads from single controller.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/DOD_2.jpg)

Ink

Traditional water-based ink often causes fading of print while exposed to sun light and variation in print quality whenever printing resumes after pausing for a few minutes. KGK Jet DOD printers use Oil based inks which do not block the nozzle and thus achieve high-resolution prints from the first print to the last run.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/DOD_4.jpg)

Compact Size and Ergonomic Features

KGK's DOD printers are compact in size and adopt as per customers need. Minimal change in your existing line delivers faster uptime. Unique touch panel helps users to input data and make changes fast & easily.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/TIJ_1.jpg)

Maintenance Free

KGK Jet Thermal inkjet printers require minimal maintenance because there is no pump and no moving parts. The print head requires only occasional cleaning.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/TIJ_3.jpg)

High Resolution

Thermal printers deliver high-resolution prints up to 600 DPI with different level adjustments. There is no chance of the cartridge leaking because the ink and print head are housed in the same cartridge.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/TIJ_2.jpg)

Cost-Effective

KGK Jet uses patented HP cartridges. Our unique TIJ technology for thermal inkjet coders promises error-free prints with maximum uptime and reduced cost when compared with other printers.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/TIJ_4.jpg)

Increased Height of the Print

We can achieve an increase in print height by stitching together multiple print heads. The thermal inkjet coder or carton box printer can print character heights upto 49.5 mm height with 4 heads stitched together.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/laser-1.jpg)

Low Heat Affect Zone

Unlike CO2 and Fiber lasers, our 355nm laser wavelength produces minimum heat affected zone on the marking area. This enable us to mark on heat sensitive substrate without damaging it, which results in superior and precision marking. Especially suitable for sensitive electronic components and sensors.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/laser-3.jpg)

Small Spot Size:

KGK Jet UV laser deliver 100 times smaller spot size than CO2 laser. This allow UV laser to deliver more density of laser using lesser power, results in more efficient and accurate marking.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/laser-2.jpg)

Wide Application & Substrate

Ideal choice for marking applications, as UV laser has relatively higher absorption at 355nm wavelength, for most substrates. Now laser mark, Logo, batch, serial number & graphics on almost any substrate even laser mark low-voltage apparatus and refractory materials.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/laser-4.jpg)

Service Support

Unlike other marking methods KGK UV Laser doesn’t require consumable like inks and solvent or cleaning solution to operate. Enjoys maximum uptime with minimum maintenance with help of KGK pan India service network.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/PrintExaminer_1-min.jpg)

Easy to view with simple operations

Highly responsive 8 inch & 10.4-inch colour touch panel let you select the desired area for selection. You can create inspection settings by measuring the actual object using bounding boxes instead of inputting numerical values.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/PrintExaminer_3-min.jpg)

Save installation space

Easy integration to your existing line allows freedom to install in a variety of ways, such as attaching to a camera stand or conveyor frame.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/PrintExaminer_2-min.jpg)

High Resolution input

Freedom to select high-resolution cameras in addition to standard cameras. Allow customer to set high-resolution camera to inspect with high precision, for example, minute missing dots such as border lines printed by a high-resolution printer.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/PrintExaminer_4-min.jpg)

Most reliable inspection device

Unlike conventional inspection system KGK Jet PK series can read after reading & compare the barcode, with the text. Can be used not only for quality control of barcode printing, but also for checking for contamination of different materials. Possible to share high reliable data between two auxiliary storage devices (HDD and SSD), during scheduled maintenance for long-term continuous production lines.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/INK_1-min.jpg)

Precision engineered to perfection

KGK Jet inks are precision engineered to perfection through years of research & development. This ink has to stay in continuous motion, withstand high pressure and pass-through tiny nozzles, get hammered into droplets. Within milliseconds go through numerous charge and discharge cycles and pass-through high voltages. While very same ink has to maintain constant viscosity inside the machine, it should dry instantly when it comes in contact with the product.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/INK_3-min.jpg)

In-house ink development

Industrial inkjet printers print on a wide variety of materials, including cardboard, metals, plastics, ceramics, and food, and each has different quality and performance requirements. In order to meet the diverse needs of the market, KGK Jet is able to develop ink raw materials in-house and has an ink development department that develops unique inks.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/INK_2-min.jpg)

Vast industrial customers

We develop inks that are ideal & optimal for printing on a variety of substrate, regardless of industry such as food, beverages, pharmaceuticals to electronic equipment, automobiles, and building materials.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/INK_4-min.jpg)

Special inks

We are developing inks with unique functions, that can be printed directly on foods and tablets, inks that harden and fix when exposed to ultraviolet light, and inks made from metal nanoparticles that can be used to form electronic circuits and wiring.

Let KGK JET give you the

Clear, Precise Print

Contact us Now

Copyright © KGK Jet India. All Rights Reserved.

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/fmcg.webp)

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/scheduler-min.jpg)

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/Language-min.jpg)

/filters:quality(20)/filters:proportion(0.4)/printers.kgkjetindia.com/CCSR.webp)

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/CCS3000L.webp)

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/CCS3100.webp)

/filters:quality(100)/filters:proportion(1)/printers.kgkjetindia.com/HQ1500.webp)

/filters:quality(100)/filters:proportion(1)/ecm.elcom-in.com/Basic-rack-PDUs-V.jpg)

/filters:quality(100)/filters:proportion(1)/ecm.elcom-in.com/Basic-rack-PDUs-H-1.jpg)

/filters:quality(100)/filters:proportion(1)/ecm.elcom-in.com/Basic-rack-PDUs-Din-rail-1.jpg)